20-50KG bag unloading machine consists of bag conveyor, bag cutter,sieving&conveyor,dusting and waste bag collector.Fast speed, low power consumption, good environmental protection. The equipment is suitable for mineral, chemical, building materials, grain, feed and other industries.

1. Product Features

- High efficiency and less labor. The speed can up to 40 bags per hour. No need to hang bag, waste bag and pallet will be handled automaticly.

- Excellent dust control.Fully enclosed structure, realizing synchronous dust collection.No dust leakage is visible to the naked eye.

- High service life. The high strength wear-resistant material cutter better ensures the service life.

- High stability.The optimized design and institutional analysis, combined with dynamic long-lasting experimental calibration, hydraulic lifting control, etc., ensure the stability.

- Well-arranged space.

- Flexible design layout.

1.1 Main purposes and scope of application

The equipment covered by this manual is intended for use in a variety of operations under normal conditions. If used for other purposes or in potentially hazardous environments, special safety regulations must be followed and the equipment must be equipped with equipment suitable for the corresponding purpose.

- Fine chemicals: pigments, dyes, coatings, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieve, kaolin, silica gel powder, activated carbon, etc.

- Pesticide ores: urea, ammonium chloride, ammonium bicarbonate, soda ash, solid pesticides, tungsten powder, pesticide additives, copper concentrate powder, coal powder, phosphate rock powder, alumina powder, etc.

- Building materials: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, sawdust powder, glass fiber, silica, talc powder, etc.

1.2 Use environmental conditions

It is suitable for places where the ambient temperature does not exceed 40℃ and the humidity is 95%. The maximum working temperature of the motor does not exceed 95℃.

2. Structural features and working principle

2.1 Overall structure

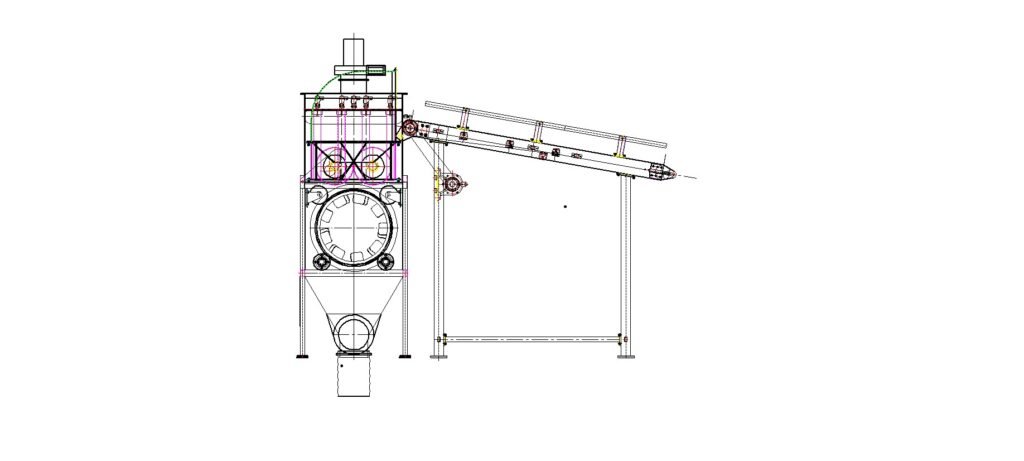

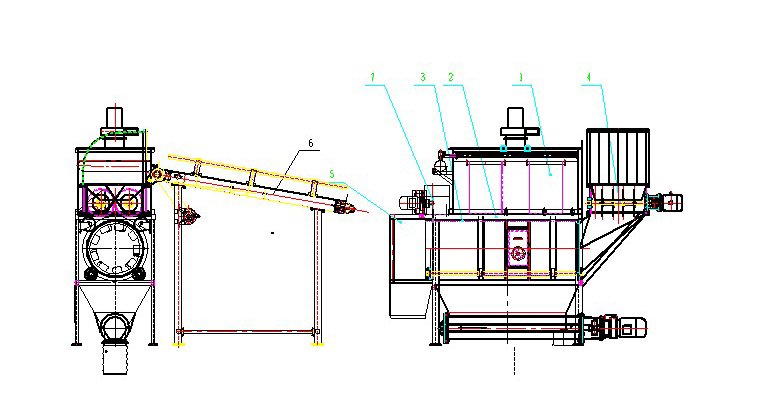

MCD series is composed of dusting device, frame, tumbler screen, cutter set, outlet cover and belt conveyor.

1. dusting device 2. frame 3. tumbler screen 4. cutter 5. outlet conver 6. betl conveyor 7. sprocket wheel

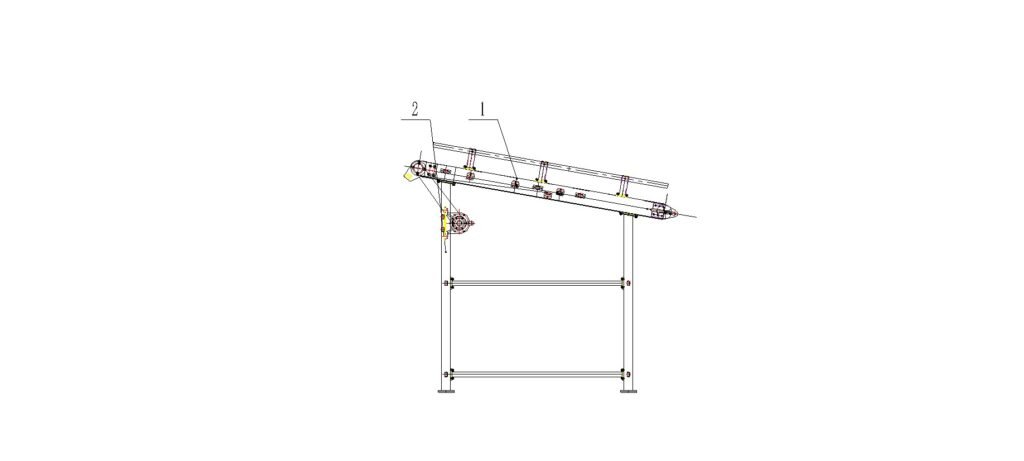

2.2 Climbing conveyor

Belt conveyor

Machine body

The whole machine is on the pre-buried foundation, and the end support of the beam is fixed, so the stability is reliable.

1. Frame 2. Roller device 3. Roller axle

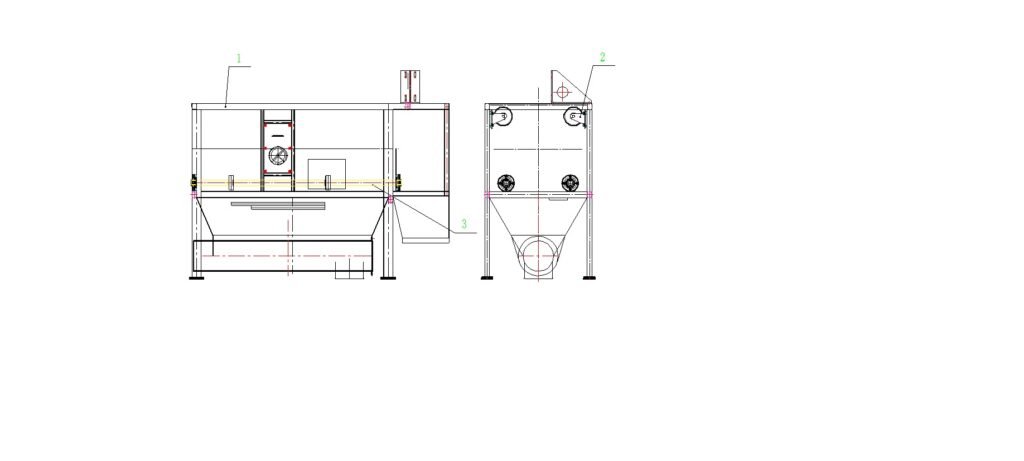

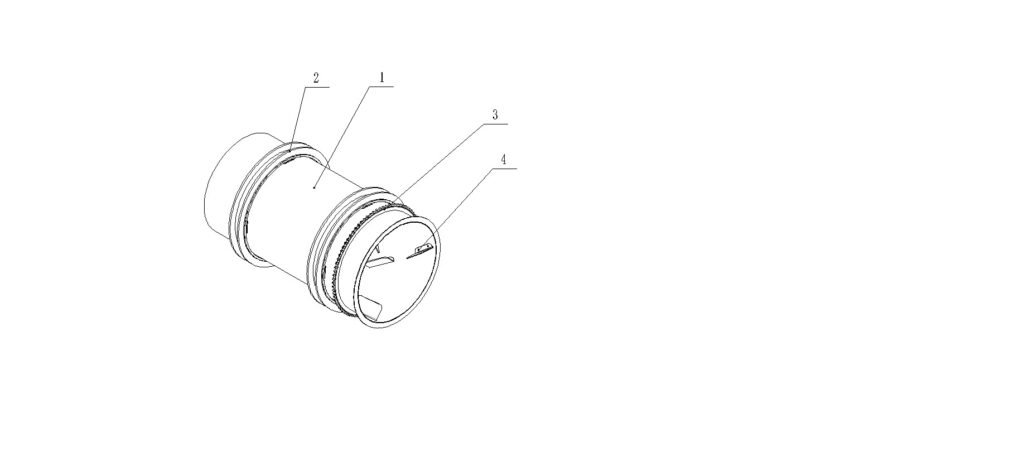

tumbler screen

It is used to separate the material from the bag.

- 滚筛tumber 2. 滚圈roller 3. 链轮sprockets 4. 叶片blade

Cutter: Cut the bag

Dust collection

The sintered plate dust collection system is integrated with the host machine to meet the negative pressure operation of the equipment, realizing the self-flow of dust collection materials into the warehouse without additional storage; the material door switch is closed for unpacking, completely isolated from the outside world, realizing dust-free unpacking operation.

Control system

Setting the control switch, it can be operated to lift bag into the machine, cut the bag, discharge the material and outlet the waste bag.

The whole machine is on the pre-buried foundation, and the end support of the beam is fixed, so the stability is reliable. It can lift one ton.

2.3 Principle of operation and main components

Before using the machine, please understand the contents of this manual

If the equipment is operated in accordance with the procedures stated in this manual, it will operate safely and completely. If not , our company is not responsible for any consequences that may occur.

Our products are technically revolutionized with new developments.

Electrical machinery and equipment are used in current industries. And it will be highly susceptible to hazards in their application,If not operated in accordance with safety instructions. For this reason, it is necessary to eliminate unauthorized movement, improper use, incorrect operation or unreasonable maintenance, which may result in personal injury or property damage.

3. Technical characteristics

Equipment specifications and performance parameters

Bag weight: 30-50kg

Voltage: AC 380 V±5% 50 Hz

Air pressure: ≥ 0.6MPa

Air consumption: ≤ 1.2 m³/min

Air rate for dedusting: 1200m³/h

Relative Humidity: ≤80%

Temperture: -10℃-40℃

4. Transportation

4.1 Safety warning

External supporting products with safety and explosion-proof performance requirements must be selected according to the supporting manufacturer

Electrical devices must be operated in accordance with the requirements of “It is strictly prohibited to open the cover while the power is on” on the warning signs everywhere;

4.2 The machine disintegrates during transportation

The degree of decomposition of the equipment is determined based on the actual dimensions of the vehicle (length, width and height), transportation capacity, and weight of the equipment.

4.3 Precautions during transportation

- When transporting by trolley, the load-bearing capacity of the trolley should be fully considered. When loading goods, the protection should be strengthened and the moving mechanism should be prevented. When fastening with wire ropes, equipment damage and scratches should be prevented.

- Small items such as pins and bolts should be transported together with the corresponding disassembled parts.

- Electrical equipment must be covered with plastic film.

4.4 Hoisting of the machine

To ensure smooth installation, important parts are taken as examples to explain their installation methods.

- The height and width of the place where the equipment is installed should not be less than 5m.

- During installation, the safety and convenience of transportation and installation operations should be fully considered

- The order of each component of the machine is determined according to the order of installation;

- Equipment must be bundled securely when loading into the vehicle to prevent components from moving up and down during transportation. It is strictly forbidden for components to extend beyond the outside of the vehicle;

- During the installation process, the lifting operation must be handled with care to avoid damaging components, pipelines, etc.

- The layout method of the hoisting machine can be determined according to the equipment conditions. The hoisting beam can be either steel pipe or heavy rail.

Anqiu Boyang Machinery Manufacturing Co., Ltd. is a research and development “production + service” enterprise focusing on automatic packaging and palletizing, robot de-palletizing and unpackaging machine, tube chain conveyor quantitative feeding and intelligent storage and logistics equipment customization, and is also a set of import and export of international trade, e-commerce, Internet marketing in the integration of science and technology innovation enterprise.

The main products include automatic bagging and palletizing production line, Intelligent unbagging and depalletizing feeding line, automatic loading and unloading robot, intelligent AGV handling robot, intelligent three-dimensional warehouse, etc. The intelligent production lines of warehousing and handling logistics equipment are used in warehouses, stations, yards, terminals and other packaging, loading and unloading, transportation and storage industries, covering more than 20 industries such as chemical, pharmaceutical, rubber, plastic, feed, grain, food, building materials, coal, metal ore, non-metallic ore, hazardous waste, new energy, etc.

It is the “small giant” enterprise of Ministry of Industry and Information Technology, national intellectual property advantageous enterprise, high-tech enterprise, single champion manufacturing enterprise of Shandong Province, potential champion cultivating enterprise of Shandong Province, the enterprise technology innovation enterprise in shandong province, specialized in special new enterprise of Shandong Province, top 100 innovation potential enterprise of Shandong Province, intelligent manufacturing model enterprise of Shandong Province, service manufacturing demonstration enterprise of Shandong Province, potential champion enterprise of Weifang City, etc, Shandong Smart Manufacturing model Enterprise, Shandong Service-based Manufacturing Demonstration Enterprise, Weifang Potential Champion Enterprise, etc.